PVDF fluorocarbon coating

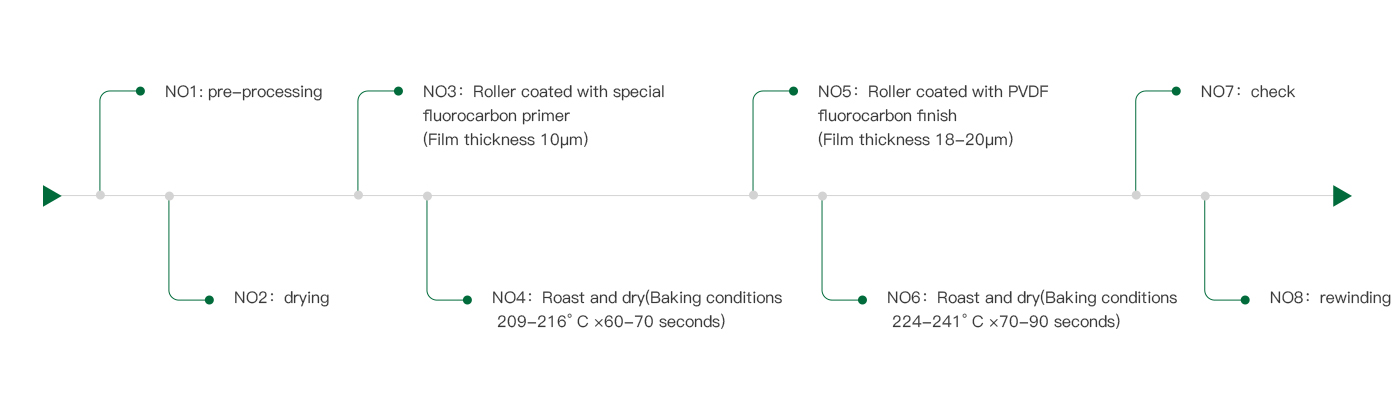

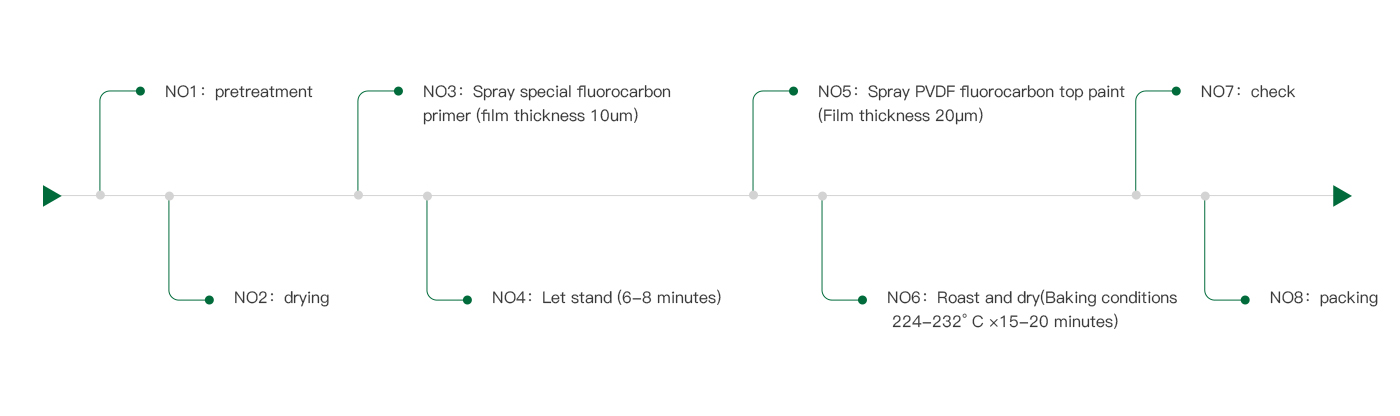

The fluorocarbon coating developed by the company is a new type of thermosetting coating for precoated coil based on DuPont's polytetrafluoroethylene as the main film forming material, it in the coating of weather resistance, hardness, stain resistance, resistance It is far more than other film forming materials in acid and base, and is the king of modern outdoor building decoration materials. The excellent performance of PVDF fluorocarbon coatings is due to the special chemical structure of the product, due to the carbon-fluorine bond In addition, only a small proportion of UV photons (≤220nm UV wavelength) in sunlight can destroy C-F bond. Sunlight has almost no effect on fluoropolymers, so fluoropolymers have ultra-high weather resistance.

浙公网安备33108202000778号

浙公网安备33108202000778号